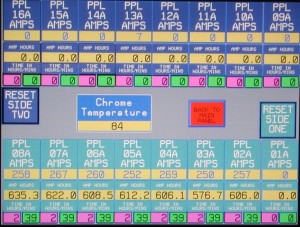

MRO Control Screen

Whyco Finishing Technologies has been a certificated FAA Repair Station since 2004, with an Airframe, Powerplant, Propellers, & Accessories rating. Whyco has the capabilities to process components from all manufacturers and for all makes and models.

The Maintenance, Repair & Overhaul (MRO) Process Cell, utilizing Whyco’s chemical and engineering technology in conjunction with FAA and Original Equipment Manufacturer’s approved technical data, performs specialty chemical cleaning, abrasive blasting and chemical removal of inter-metallic wear or heat resistant coatings on critical commercial aircraft components.

Whyco also specializes in the electroplating of hard chromium and low stress, ductile nickel onto worn parts for the purpose of restoring them back to dimensional tolerances.

Whyco’s MRO Process Cell is housed in a secure, segregated 8000 square foot production area. Thirty-five large tanks with the capacity to process parts up to 60 inches in diameter can perform more than forty processes to meet the repair specification requirements for airframe, engine, and accessory manufacturers. All critical processing parameters are controlled, monitored and recorded by state-of-the-art manufacturing software.

Focusing on quality, price and delivery, Whyco Finishing Technologies’ MRO Business Unit is described by the industry as a “Center of Excellence”.

WFT FAA Repair Station Process Cross Reference Spreadsheet

FAA Repair Station #W63R974X